PowerfulHardwarecutting edge monitoring control hardware

Data Logger and Power Plant Controller

Data Logger & Power Plant Controller

The Q.reader offers reliable and flexible solutions for the park control of utility scale and industrial and commercial (I&C) PV power plants. The Data Logger can record several thousand data channels with a resolution of up to one second. With functions like voltage regulation, reactive or active power control, and control of power factor at the grid connection point all Distributed Network Operator (DNO) requirements are provide to maximize grid stability. The real time Linux based Q.reader has multiple input and outputs for the signal connections. The module concept allows flexible upgrade of the number of inputs and outputs. The Gantner Instruments Plant Controller provides all functionality for the Smart Grid for today and tomorrow

Q.reader cabinet "QRC"

The “Q.reader cabinet” is an fully customized solution based on the specific customer and individual project requirements. All switchgear cabinets are manufactured "Made in Zwoenitz/Germany“ in compliance to IEC 61439 Low-voltage switchgear and control gear assemblies. The production process is ISO 9001 certified to reach the high-quality goal of Gantner Instruments.

Field Point Extension "FPE"

Field Point Extensions are fully customized add-on cabinets to the “Q.reader” data logger which provide data acquisition within the entire PV plant, such as string level (current, voltage), inverter data, meteorological data from weather stations, grid measurements and other state variables (switch gear, transformer status). Usually one FPE per transformer station is applied and information from all FPEs will be sent to the central data logging and control unit QRC by fiberoptic.

DC/AC Combiner Boxes

DC string combiner box "DCCBs"

With the integrated string.bloxx it is possible to monitor inverter-independent precisely the DC side of photovoltaic systems.

AC combiner box "ACCBs"

The Gantner AC Combiner boxes provides the optimal interface between inverter and grid in decentralized energy generation plants.

String monitoring devices

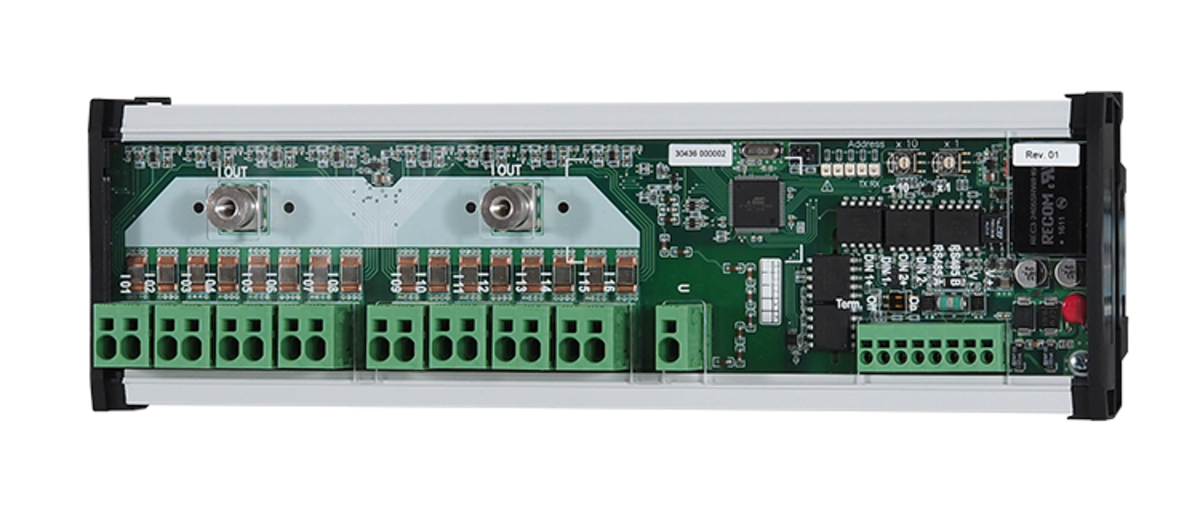

String.bloxx 116 EM 1000V/1500V

String.bloxx 116 EM are devices for accurate measurement of string currents and voltages for up to 16 string inputs. Also double string input per measurement channel is possible.

String.bloxx 124 EM 1000V/1500V

String.bloxx 124 EM are devices for accurate measurement of string currents and voltages for up to 24 string inputs. Also double string input per measurement channel is possible.

Shunt module

High precise passive shunt module for measure PV strings in combination with the Gantner Q.bloxx A127 series.

Wireless module

Thanks to the wireless RF.bloxx 101 it is possible to provide string monitoring without either communication cable nor power supply cable. This is a big advantage especially for retrofitting PV power plants with string monitoring devices.

Distributed IOs

Distributed IOs

With help of our Distributed I/Os we are flexible to extend our measure and control network. Distributed input/output systems generally send control signals and read sensor measurements over a communication network. The network links the central Q.reader controller to several nodes located around the power plant.

Meteo sensors and complete meteo stations

Meteo stations

The Meteo station standard consists of a wall-/rack-mounted meteo.boxx (two central DAQ units for data collection and sensor connections) with easy to mount panel-construction for sensors.

Meteo sensors

The Meteo station standard consists of a wall-/rack-mounted meteo.boxx (two central DAQ units for data collection and sensor connections) with easy to mount panel-construction for sensors.

Get in touch and let's start together

We are happy to advise you on your project and to help you to solve your challenges. We look forward to your inquiry.

Start inquiry now